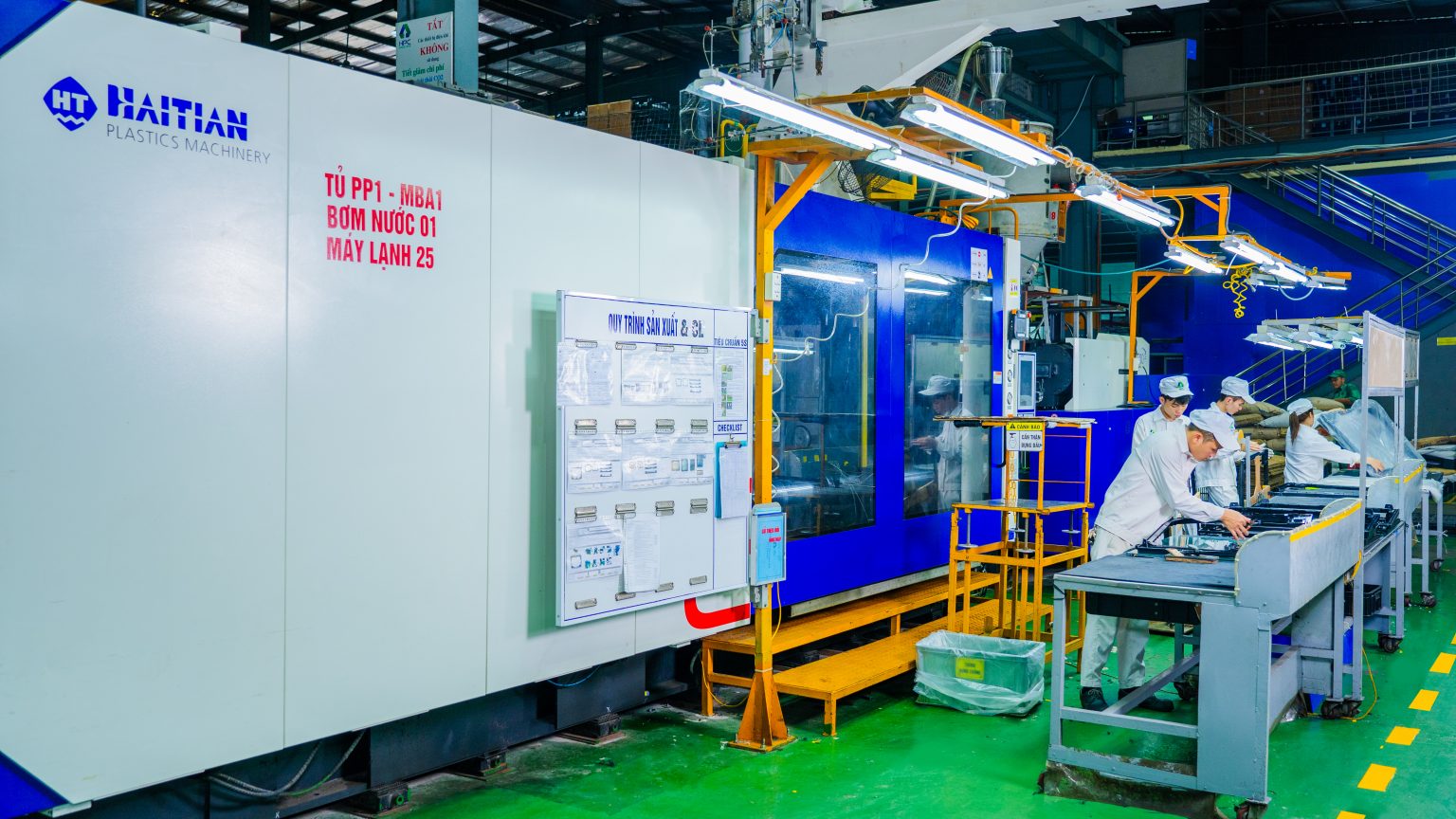

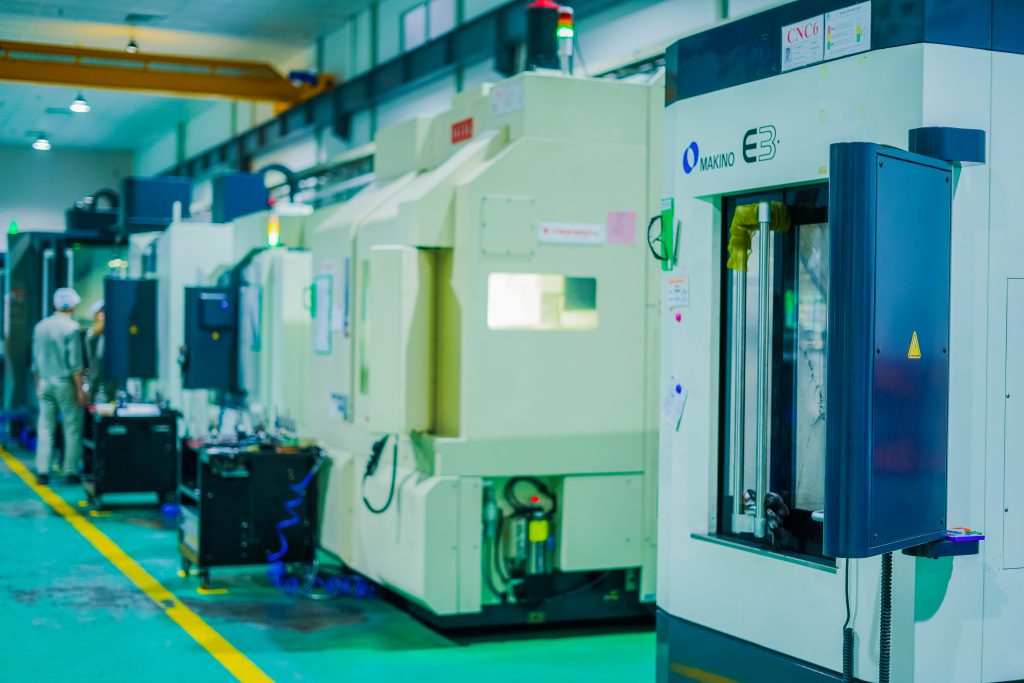

Hanoi Plastics (HPC) owns a large-scale factory system, equipped with synchronous, modern, and imported machinery and equipment from the US, Western European countries, Japan, and newly industrialized countries (NICs) with high specialization in mechanization and automation.

Hanoi Plastics’ factories have a strict quality control system, which is certified by prestigious organizations around the world following international standards such as ISO 9000, ISO 14000, and particular customers’ standards (such as TS Standard of Toyota, HES Standard of Honda..)